Working Principle of Dropout Fuses

The working principle of drop-out fuses is based on the thermal effect of current. When the current in the circuit exceeds the rated current of the fuse, the dropout fuse wire melts due to overheating, thereby cutting off the circuit and protecting it from damage.

Normal working condition: In normal working conditions, the fuse remains intact, the circuit is closed, and the current can pass through smoothly.

Overload or short circuit condition: When an overload or short circuit occurs in the circuit, the current increases sharply. The fuse quickly heats up and melts due to the thermal effect of the current, causing the circuit to open.

Selection of Fuse Wires for Dropout Fuses

The selection of fuse wires is critical to the performance of the fuse. The rated current of the fuse wire should be slightly higher than the normal working current of the circuit to ensure that it does not melt under normal working conditions. At the same time, the blow characteristics of the fuse wire should match the protection requirements of the circuit to ensure that it can quickly cut off the circuit during overload or short circuit conditions.

Drop Action of Dropout Fuses

After the fuse wire melts, the fuse tube will automatically drop due to gravity, an action referred to as the drop action. The purposes of the drop action are:

Isolate the fault section: Quickly isolate the fault section from the grid to prevent the fault from spreading.

Facilitate maintenance: The dropped fuse tube is easy to replace, facilitating maintenance work.

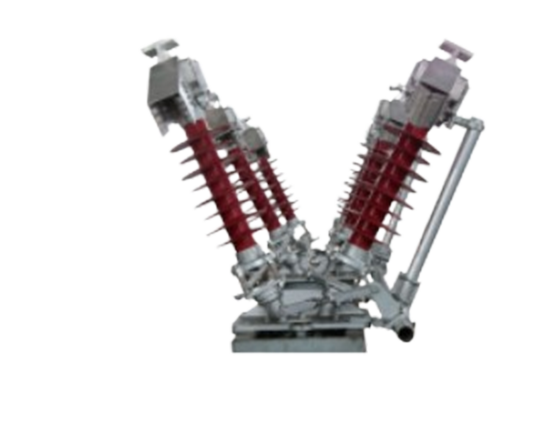

Operating Mechanisms of Dropout Fuses

The operating mechanism can be either manual or electric. Manual operating mechanisms are usually used in small distribution systems, while electric operating mechanisms are used in large distribution systems to achieve remote control.

Manual operation: Operators use a manual operating lever to drop the fuse.

Electric operation: The electric mechanism enables remote control of the fuse drop, enhancing operational safety and convenience.

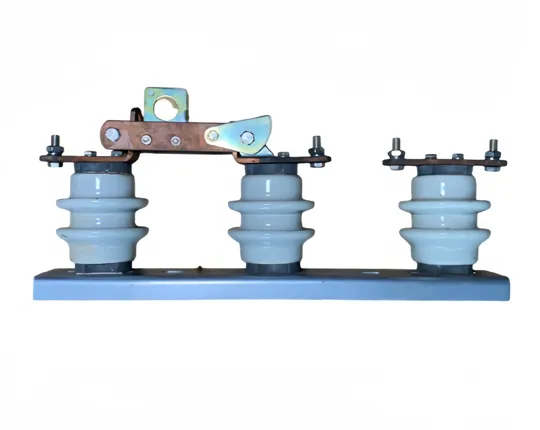

Base and Insulator of Dropout Fuses

The base and insulator function to fix the fuse and ensure its electrical isolation from the conductive parts. The insulator material usually has excellent insulating properties to ensure the safe operation of the fuse in high-voltage environments.

Advantages and Disadvantages of Dropout Fuses

Advantages:

Simple structure, easy maintenance.

Quick action, good protection performance.

Relatively low cost, suitable for a wide range of applications.

Disadvantages:

Requires regular inspection and replacement of fuse wires, resulting in a higher maintenance workload.

Sensitive to environmental conditions; factors such as humidity and temperature may affect performance.

Application Scenarios for Dropout Fuses

Distribution networks: Used to protect distribution lines from overload and short circuits.

Transformer protection: Used to protect transformers from damage due to overload or short circuits.

Motor protection: Used to protect motors from overload and short circuits.

Maintenance and Inspection of Dropout Fuses

Regular maintenance and inspection are crucial to ensuring the normal operation of drop-out fuses. Maintenance tasks include:

Checking the fuse wire: Regularly check the condition of the fuse wire and replace any damaged wires promptly.

Cleaning the insulator: Regularly clean the insulator to prevent dirt and contaminants from affecting its insulating performance.

Inspecting the operating mechanism: Ensure the operating mechanism is flexible and reliable, repairing or replacing damaged components in a timely manner.